WARKO's working principle

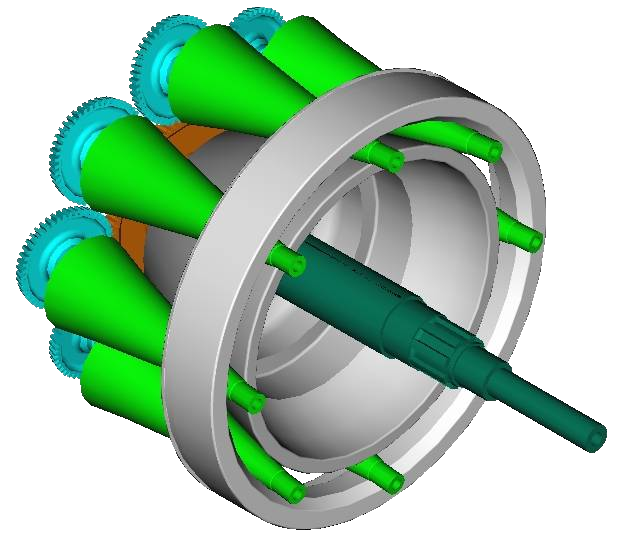

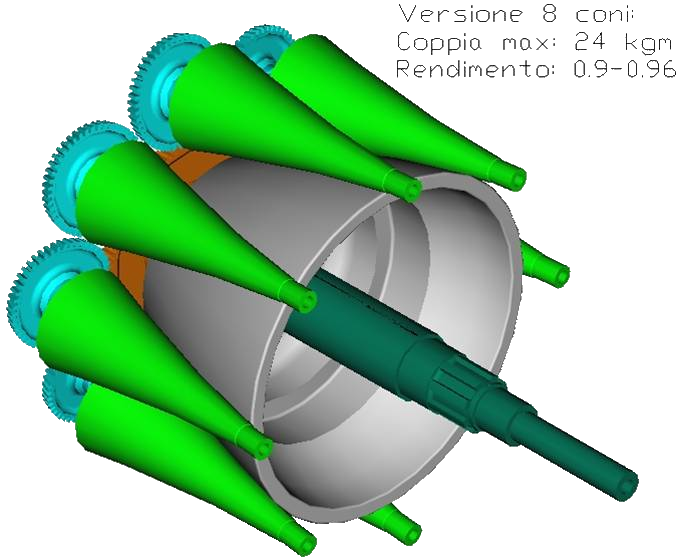

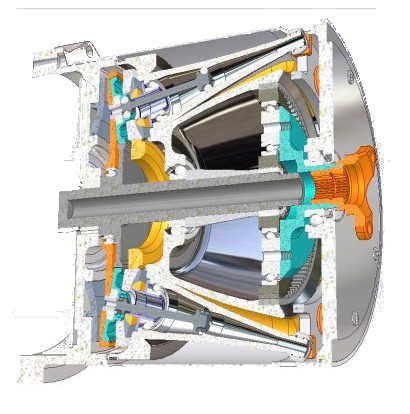

Starting from the complete configuration of all the components needed for the transmission of motion (figure at right) try to break down the individual steps in the assembly of the CVT Warko to understand the principle of operation.

Starting from the complete configuration of all the components needed for the transmission of motion (figure at right) try to break down the individual steps in the assembly of the CVT Warko to understand the principle of operation.

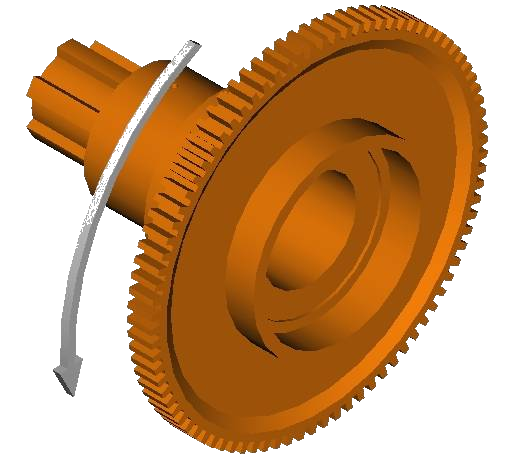

Coming from the engine shaft, motion is transmitted to the main gear, called "solar".

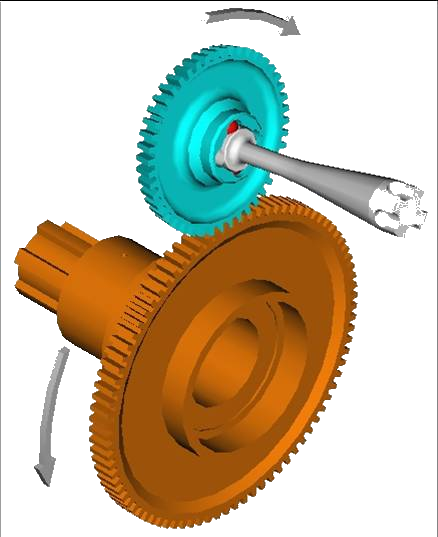

From solar, the motion is transmitted to the "N" gear arranged in a ring on it, called satellites.

From solar, the motion is transmitted to the "N" gear arranged in a ring on it, called satellites.

For each of these satellites is connected by means of a shaft and two joints. A conical body later known Cone satellite. The side surface of the cones satellites is concave according to a given radius of curvature.

For each of these satellites is connected by means of a shaft and two joints. A conical body later known Cone satellite. The side surface of the cones satellites is concave according to a given radius of curvature.

All satellites transmit cones friction the motion to a central hub having a shape of a "barrel".

All satellites transmit cones friction the motion to a central hub having a shape of a "barrel".

Finally, the motion is transmitted to the output shaft via an internal gear (not visible in the figure)

Finally, the motion is transmitted to the output shaft via an internal gear (not visible in the figure)

The side surface of the hub is convex according to a given radius of curvature, smaller than the radius of concavity of the cones. In this way we will have a single point (theoretical) contact between the cone and barrel.

Being able to tilt the cone (swinging) on the barrel, thus realizes all possible pairs with diameters in the same barrel, according to a range of ratios ranging from 1:1 to 1:6 (besides being able to achieve a ratio of reverse )

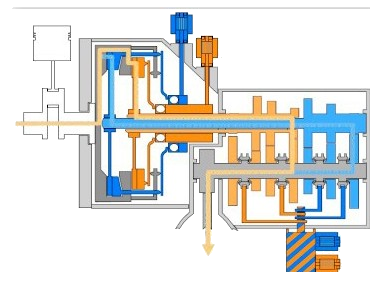

The figure shows the pattern of transmission operation Cluch Dual (Double Clutch ), which is to say of Mr Andrew Fulbrook , manager of European powertrain forecasts at CSM Worldwide in London in an interview with Automotive News ( Douglas A. Bolduc June 2005 "Dual clutch to shift past CVT " ) would put the final nail in the coffin of the CVT ! .

The figure shows the pattern of transmission operation Cluch Dual (Double Clutch ), which is to say of Mr Andrew Fulbrook , manager of European powertrain forecasts at CSM Worldwide in London in an interview with Automotive News ( Douglas A. Bolduc June 2005 "Dual clutch to shift past CVT " ) would put the final nail in the coffin of the CVT ! . In CVT Warko , thanks to the wide excursion of the transmission ratio is possible to adopt a design solution that allows to realize the function of reversing without the need to use a clutch. In the figure it can be observed that there is friction inside the bell but is inserted an epicyclic gear train called power split . As you can see , the solar train of gears is fixed to the input shaft , the crown is moved by the drive with opposite direction of rotation , is connected to the planetary finally the ' output of the entire system .

In CVT Warko , thanks to the wide excursion of the transmission ratio is possible to adopt a design solution that allows to realize the function of reversing without the need to use a clutch. In the figure it can be observed that there is friction inside the bell but is inserted an epicyclic gear train called power split . As you can see , the solar train of gears is fixed to the input shaft , the crown is moved by the drive with opposite direction of rotation , is connected to the planetary finally the ' output of the entire system .